engineering portfolio

Based on our entity dataset and background of over 40+ rocket flights, we offer the reliability and heritage for complete solutions, from consulting up to delivery of whole fin assemblies incl. qualification tests and mission support.

Portfolio:

- Rocket Fins, Canards and Hypersonic Consulting

- Technology and Design

- Handling and Ground Equipment

- Testing

- Fin Alignment

- High Temperature Junctions

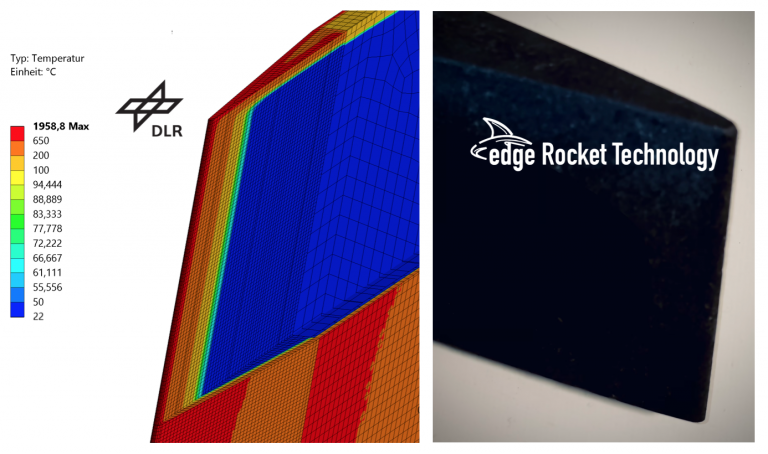

- Thermo-Mechanical Fin Lay Out Design

- CAD 1

- FEA 2

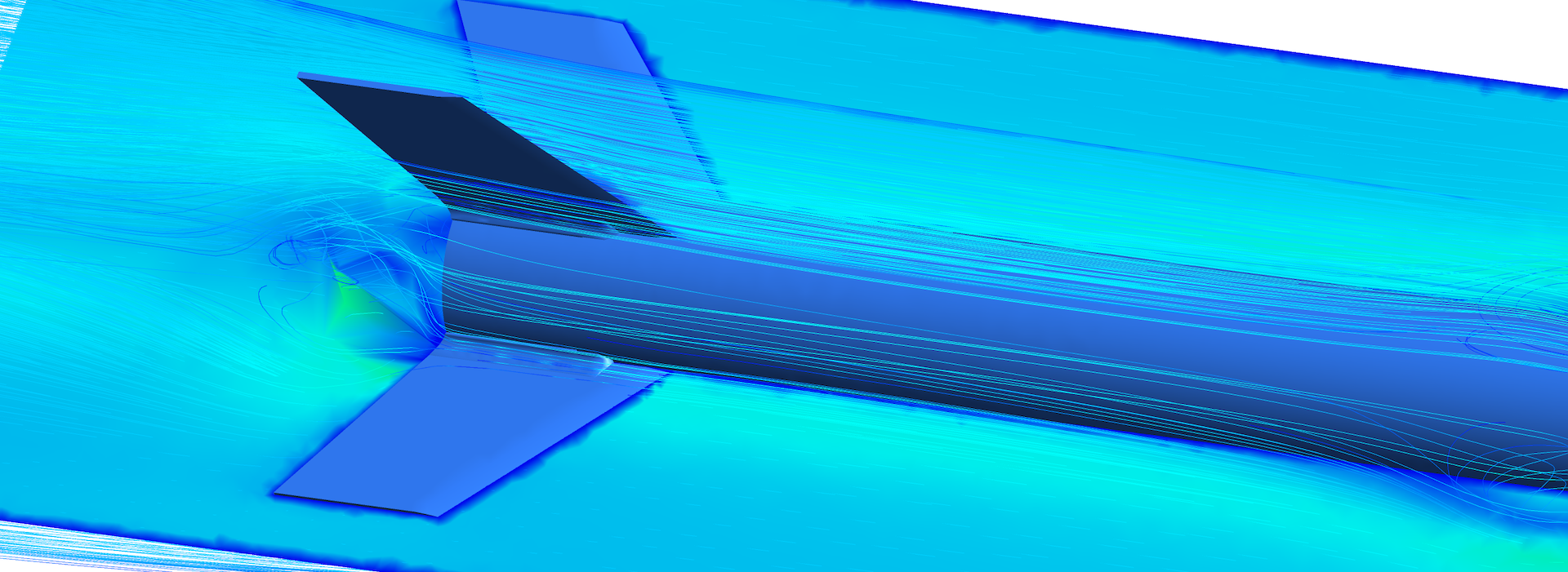

- Fin Dimensions up to approx. 1.5m2

- Optional controllable Surface

- Folding Systems

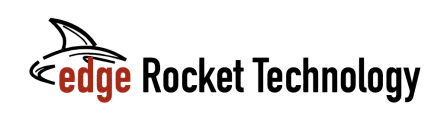

- Up to Mach 15+

- Modular lightweight/cost effective hybrid Technologies to Customer Needs

- Metallic or optional CFRP 3 and CMC 4 Design

- Optional TPS Systems

- Optimized Fin Geometries (e.g. Double-Wedge Design)

- Adaptable Leading Edge Solutions:

- Density

- In-Flight Degradation

- Processing Time

- Fin Assembly Design

- Incl. Tailcan

- Incl. Fin/Tailcan Interface

- Incl. Tailcan/Motor Interface

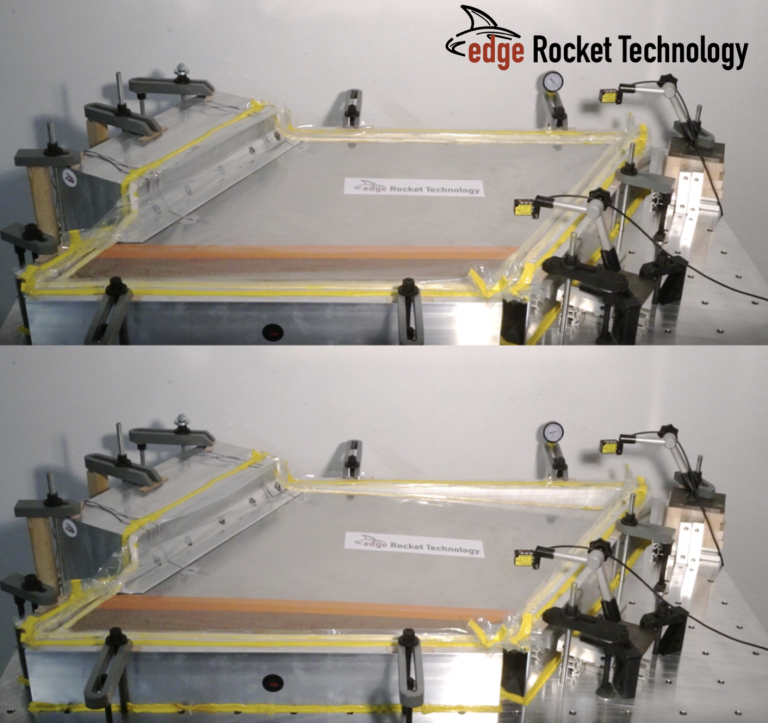

- Optimized Fin Manufacturing Process

- Reduced Processing Time

- Overall higher cost-effective PPU 5

- In House Production

- Best Quality-Control

- Low Error-Proneness

- Lean-Manufacturing

- Prototyping

- Qualification Test

- Optional Mission Support

- High Scalability for new different Launcher Systems

With this heritage we started a German Aerospace Center (DLR) spin-off to offer fast and unbureaucratic solutions for the aerospace industry.

1 CAD – Computer Aided Design

2 FEA – Finite Element Analysis

3 CFRP – Carbon Fiber Reinforced Plastic

4 CMC – Ceramic Matrix Composite

5 PPU – Price Per Unit